A properly soldered connection will appear – In the realm of electronics, a properly soldered connection is a crucial aspect that ensures the functionality and reliability of various devices and components. This guide delves into the characteristics, methods, applications, and troubleshooting of soldered connections, providing a comprehensive understanding of this essential technique.

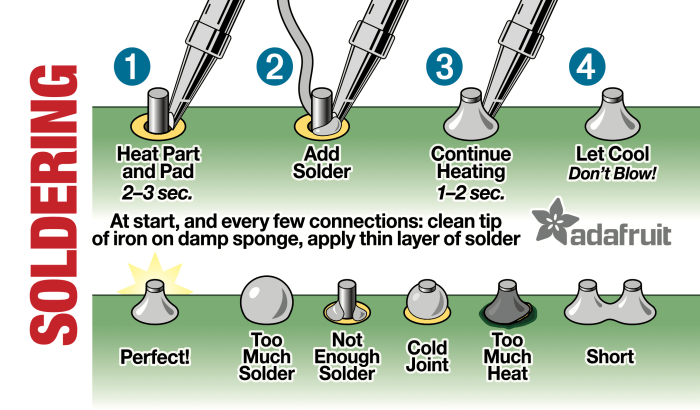

A properly soldered connection exhibits a distinct appearance, with a smooth, shiny surface that is free of voids or gaps. The solder joint should have a uniform color, typically silver or gold, and a slightly rounded shape. These characteristics indicate a strong and reliable connection that can withstand electrical and mechanical stress.

Characteristics of a Properly Soldered Connection

A properly soldered connection exhibits distinct physical characteristics that indicate its strength and reliability. These characteristics include:

- Shiny and smooth surface:The solder joint should have a glossy, even surface without any visible pits or cracks.

- Concave shape:The solder should form a concave fillet around the joint, ensuring maximum contact between the components.

- Uniform color:The solder joint should have a consistent silver or gold color throughout, indicating proper alloying and wetting.

- Strong adhesion:The solder should adhere firmly to both components, creating a secure mechanical bond.

Methods for Achieving a Proper Solder Connection: A Properly Soldered Connection Will Appear

To achieve a proper solder connection, follow these steps:

- Prepare the surfaces:Clean the components using flux or isopropyl alcohol to remove any contaminants.

- Apply solder:Use a soldering iron to melt the solder and apply it to the joint, ensuring that it flows evenly around the components.

- Remove excess solder:Once the solder has cooled, use a solder wick or desoldering pump to remove any excess solder.

Tips for Effective Soldering:

- Use a soldering iron with the appropriate wattage for the job.

- Use a flux that is compatible with the solder and components.

- Heat the joint evenly to ensure proper wetting.

- Allow the solder to cool slowly to prevent cracking.

Common Errors in Soldering

Common soldering errors include:

- Cold solder joint:Occurs when the solder does not melt sufficiently, resulting in a weak and brittle connection.

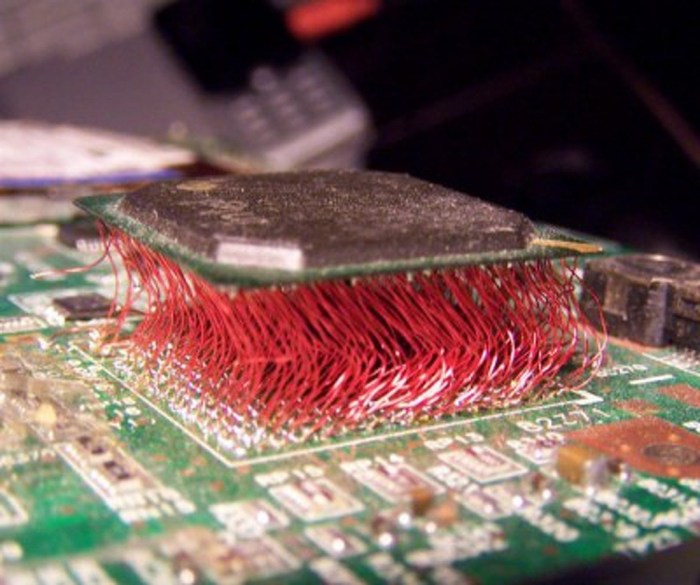

- Overheated joint:Occurs when the solder is heated too much, causing it to oxidize and weaken the connection.

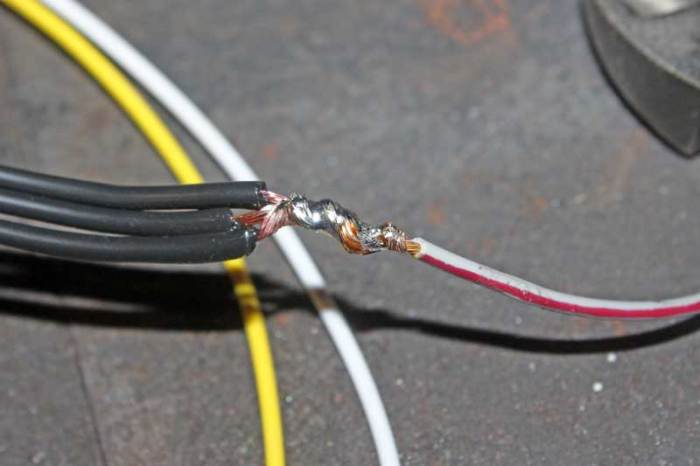

- Solder bridges:Occurs when solder flows between adjacent connections, creating short circuits.

- Insufficient solder:Occurs when not enough solder is used, resulting in a weak and unreliable connection.

- Poor surface preparation:Occurs when the components are not properly cleaned, preventing the solder from adhering properly.

FAQ Summary

What are the signs of a faulty soldered connection?

Signs of a faulty soldered connection include a dull or discolored appearance, voids or gaps in the solder joint, and a weak or intermittent electrical connection.

How can I prevent common soldering errors?

To prevent common soldering errors, ensure proper surface preparation, use the correct solder and flux, and employ the appropriate soldering techniques. Regular inspection and maintenance of soldered connections are also crucial.